Telcordia Sr-332 Handbook

Telcordia SR-332 was originally the Bell Laboratories Bellcore standard for the reliability prediction of commercial electronic components.

What’s in Telcordia SR-332?

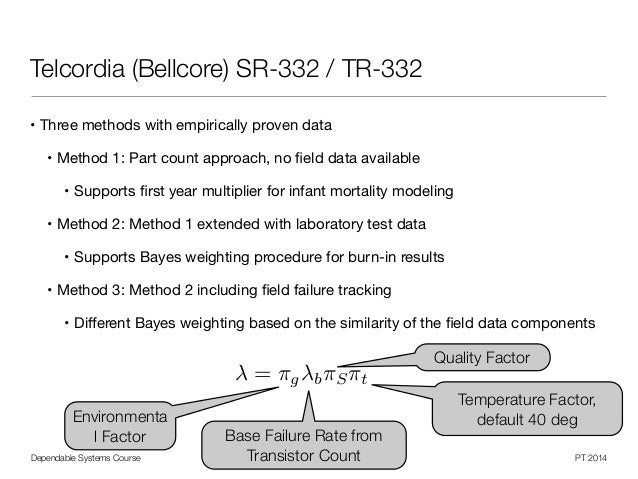

The Telcordia Standard allows reliability predictions to be performed using three methods:

- Method I provides predictions based on a Parts Count procedure.

- Method II provides predictions based on combining laboratory test data with Parts Count data.

- Method III provides predictions based on combining field tracking data with Parts Count data.

May 10, 2011 - Telcordia (Bellcore) SR-332 issue 3. • Formerly AT&T. Mechanical reliability guide. NSWC handbook / procedure for mechanical equipment. Telcordia SR-332 ISSUE 3 datasheet, cross reference, circuit and application notes in pdf format. Reliability Prediction, and Telcordia SR-332. Different from those given by the handbook method, hence. Reliability data handbook developed by French.

All three methods are handled by the Reliability Workbench Prediction Module.

What can Telcordia do?

The Telcordia SR-332 Standard also provides models for predicting the failure rates of units and devices during the first year of operation.

The failure rate during this wear-in phase is expressed as a multiplying factor operating on the predicted steady-state failure rate. This First Year Multiplier (FYM) is influenced by burn-in times and temperatures. The Prediction Module automatically calculates the First Year Multiplier based on specified system, unit and device burn-in times and temperatures.

The Overview of the Prediction Module page contains a description of the features available in Reliability Workbench for building a Telcordia SR-332 model.

Telcordia Electronic Reliability Prediction

The Telcordia Software Module of ITEM ToolKit calculates the reliability prediction of electronic equipment based on the Telcordia (Bellcore) TR-332 and SR-332 standards. These standards use a series of models for various categories of electronic, electrical and electro-mechanical components to predict steady-state failure rates which environmental conditions, quality levels, electrical stress conditions and various other parameters affect. It provides predictions at the component level, system level or project level for COTS (Commercial Off-The-Shelf Parts). The models allow reliability prediction to be performed using three methods for predicting product reliability:

It securely transfers files with lightning-fast transfer speeds, industry-leading security, and includes time-saving automation features and customization capabilities. Ipswitch ws_ftp professional 12 crack.

- Method I: Parts Count

- Method II: Combines Method I predictions with laboratory data

- Method III: Predictions based on field data

The Telcordia standard also documents a recommended method for predicting serial system hardware reliability. It contains instructions for suppliers to follow when providing predictions of their device, unit, or serial system reliability. It can also be used directly by telecommunications service providers for product reliability evaluation.

Device and unit failure rate predictions generated using this procedure are applicable for commercial electronic products whose physical design, manufacture, installation, and reliability assurance practices meet the appropriate Telcordia (or equivalent) generic and product-specific requirements.

Features

- Powerful and user friendly Telcordia telecom standard reliability prediction software

- Combine prediction methods for complex analysis

- Optimize designs to meet targeted goals

- Select components with regard to reliability and cost savings

- Be more accurate and efficient than with manual methods

- Take advantage of powerful 'what if' analytical tools

- Identify weak areas in a system design

- Build and open multiple systems and projects files

- Drag and drop components and systems between projects

- Powerful charting facilities

ITEM ToolKit's Reliability Prediction Modules

ITEM ToolKit contains five modules for performing reliability prediction (MTBF) analysis. These modules conform to MIL-HDBK-217 F Notice 2, Telcordia (Bellcore) TR-332 and SR-332, IEC 62380 (RDF 2000), China 299B GJB/z 299B (electronics) and NSWC 06 (mechanical) and share many common features and capabilities.

Each reliability prediction module is designed to analyse and calculate component, sub system and system failure rates, including Mean Time Between Failure (MTBF), in accordance with the appropriate standard. After the analysis is complete, ITEM ToolKit's integrated environment comes into its own with powerful conversion facilities for transferring data to other modules of the program. For example, transfer your MIL-217 project data to FMECA or your Telcordia project to RBD. These powerful facilities transfer as much of the available information as possible, saving you valuable time and effort.

ITEM ToolKit's Multi Document Interface allows several projects or libraries to open at the same time. Adobe acrobat 9 pro download. Prison break season 5 complete torrent download. This valuable feature comes in especially handy when it is necessary to transfer data from one project (or library) to another.

Users can construct hierarchical breakdowns of systems with no restrictions on block numbers or levels of indenture. As new sub blocks and components are added, ITEM ToolKit automatically recalculates all dependent failure rates to take account of new information.

Powerful global editing facilities are available for performing 'what if' evaluations. These facilities enable you to experiment with temperature, environmental and stress settings and see how your system performance will vary.